Valves have various types of connections like threaded, flanged, welded, tri-clamp, double union, and so on. In this article, we will share the details about flanged, threaded, and welded.

Flanged Connection Valve —Looking for a flanged valve?

Flanged valves are easy to install and disassemble, but flanged valves are bulkier and more expensive than threaded valves, so they are suitable for pipe connections of all sizes and pressures. Large-size pipelines usually uses the flanged connection.

Flanged ball valves and flanged butterfly valves are widely used in wastewater treatment, paper and pulp, shipyard, and other applications which require a flanged connection.

What is flanged end valve?

Most flanged end connections adhere to an industry standard. These standards define certain criteria that must be met to facilitate the use of products from various manufacturers.

ANSI is the American National Standards Institute. Together with the ASME (American Society of Mechanical Engineers), they have developed and published a standard for flange connections. That standard is ASME/ANSI B16.5.

There is also a European standard that is similar, but NOT THE SAME. That standard is DIN, which is an acronym for the german translation of “German Institute for Standardization.” The specific standard for pipe flanges is DIN EN 1092-1. This standard is also recognized by ISO (International Standards Organization) under ISO 7005.

SAE is the Society for Automotive Engineers. They have also developed a standard for flange type connections where the flange is separate from the components that it holds together. That standard is SAE J518. This standard is also recognized by ISO under ISO 6162.

Types of Flange Connection

Flat Face (FF)

As the name suggests, flat face flanges feature a flat, even surface combined with a full face gasket that contacts most of the flange surface.

Raised Face (RF)

These flanges feature a small raised section around the bore with an inside bore circle gasket.

Ring Joint Face (RTJ)

Used in high-pressure and high-temperature processes, this face type features a groove in which a metal gasket sits to maintain the seal.

Tongue and Groove (T&G)

These flanges feature matching grooves and raised sections. This aids in installation as the design helps the flanges to self-align and provides a reservoir for gasket adhesive.

Male & Female (M&F)

Similar to tongue and groove flanges, these flanges use a matching pair of grooves and raised sections to secure the gasket. However, unlike tongue and groove flanges, these retain the gasket on the female face, providing more accurate placement and increased gasket material options.

A Look at Flange Connection Dimensions

Apart from the functional design of a flange, flange dimensions are the most likely factor to impact flange choices when designing, maintaining, or updating a piping system.

However, you must consider how the flange interfaces with the pipe and the gaskets in use to ensure proper sizing.

Common considerations include:

- Outside diameter: The distance between two opposing edges of the flange face

- Thickness: A measure of the thickness of the outer attaching rim

- Bolt circle diameter: The distance between opposing bolt holes when measured from center to centre

- Pipe size: A designation of the pipe size with which the flange corresponds

- Nominal bore size: A measurement of the flange connectors inner diameter

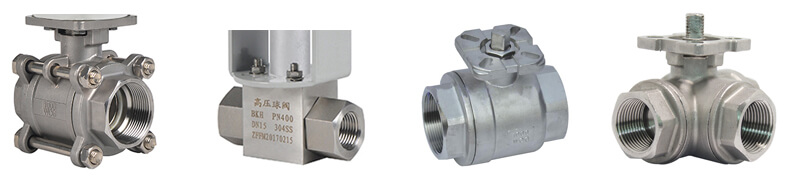

Threaded Connection Valve —Looking for a threaded valve?

The threaded connection is generally used for pipes less than 50mm. If it is larger than 50mm, we would recommend using flanges and other connection methods.

The threaded connection is divided into G, NPT, BSPP, and BSP standards, as well as female and male threads.

Types of Threaded Connection

NPT – National Pipe Thread Tapered

This is a U.S. standard for tapered threads used on threaded pipes and fittings. In contrast to straight threads like those that are found on a bolt, a taper thread will pull tight and therefore make a fluid-tight seal. Pipe tape or pipe compound should be used on the threads to ensure a fluid-tight seal.

NPT is defined by ANSI/ASME standard B1.20.1.

There are 25 sizes defined from 1/16″ to 24″, (see a chart with sizes and dimensions) however typically valves over 4″ will use flanged connections rather than threaded.

NPT threads are specified using the size in inches followed by “NPT”.

BSPT – British Standard Pipe Taper Threads

This standard is similar to NPT, where the threaded portions of the connection are tapered. The only difference is the angle of the thread flanks. The angle from root to crest on BSPT threads is 55° as opposed to 60° for NPT. A male NPT can fit into a female BSPT, but due to the difference in the thread angle, a fluid tight seal will not be made.

BSPT threads are defined by ISO 7 and/or EN 10226-1, BS 21.

BSPT threads are specified using the letter “R” followed by the size in inches. R stands for “rohr” which is german for the pipe.

BSPP – British Standard Parallel Pipe Threads

This type of thread does NOT form a fluid tight seal as the tapered threads do. The use of a soft seal is required to do so. These threads will pull the 2 mating parts together, and compress the soft seal between flat surfaces on each component.

BSPP threads are defined by ISO 228-1:2000 (Dimensions, tolerances, and designation) and ISO 228-2:1987.

BSPP threads are specified using the letter “G” followed by the size in inches. G stands for “gas”.

The threaded connection is suitable for low-pressure pipelines. Lower price.

Welded Joint Valve —Looking for a welded valve?

Welding connection refers to welding the valve and the pipe together.

Suitable for pipelines that require zero leakage, such as high temperature and high-pressure pipelines. Welding is divided into socket welding and butt welding.

Socket Weld

The valve simply has a socket with an inner diameter that is ever so slightly larger than the pipe’s outer diameter. The pipe is inserted into the socket and is welded around the rim as shown here. Socket weld connections are usually reserved for smaller sizes, typically 2″ and below. They are permanent connections that are reliably leak-free. This example includes “heat sink” fins which help dissipate heat to protect the seals during welding. Valves with this feature are often referred to as “weld-in-place.”

Note: These welds should be performed by a trained professional. Care must be taken to avoid damaging the seats and seals with excessive heat.

Butt Weld

The valve end and the pipe end are of equal diameters. The outer edge of each is chamfered to create a “valley” to be filled with welding material. The two pieces are welded around the rims as shown in the illustration. Butt weld connections are usually reserved for smaller sizes, typically 2″ and below. The example shown here also includes the heat sink fins.

Note: These welds should be performed by a trained professional. Care must be taken to avoid damaging the seats and seals with excessive heat.

PS: Welding requires professionals to operate.

All of the threaded, flanged, and welded valve with ISO5211 mounting standards for electric actuators and pneumatic actuators.

Don’t figure out which connection should use? Contact us and we will help you to choose the suitable one.

Related Tags :

Ten articles before and after

News – Application Of Valves In Water Supply System | API approved valve manufacturer

News – 6 Characteristics Of Valve | API approved valve manufacturer

News – The Development Course Of Valve | API approved valve manufacturer

News – Modular Intelligent Electric Valve Controller | API approved valve manufacturer

News – Function Of Pneumatic Valve Positioner | API approved valve manufacturer

News – 12 Features Of Electric Actuator | API approved valve manufacturer

News – The Difference Between Hydraulic Actuator, Pneumatic Actuator And Electric Actuator | API approved valve manufacturer

News – Why To Choose Electric Actuator Valve According To The Working Environment? | API approved valve manufacturer

News – What Valves Used In Sewerage System? | API approved valve manufacturer

News – Maintenance Principles Of Valve | API approved valve manufacturer