Choosing the right ball valve is a deciding part of your project. Types of ball valves depending on the type of ball design can be divided into Floating Ball Valve and Trunnion Ball Valve. Trunnion mounted ball valve and floating ball valve are two of the most common ball valves. Each of them has its characteristics and advantages. Knowing the difference between floating and trunnion ball valve will help you choose the best one for your project.

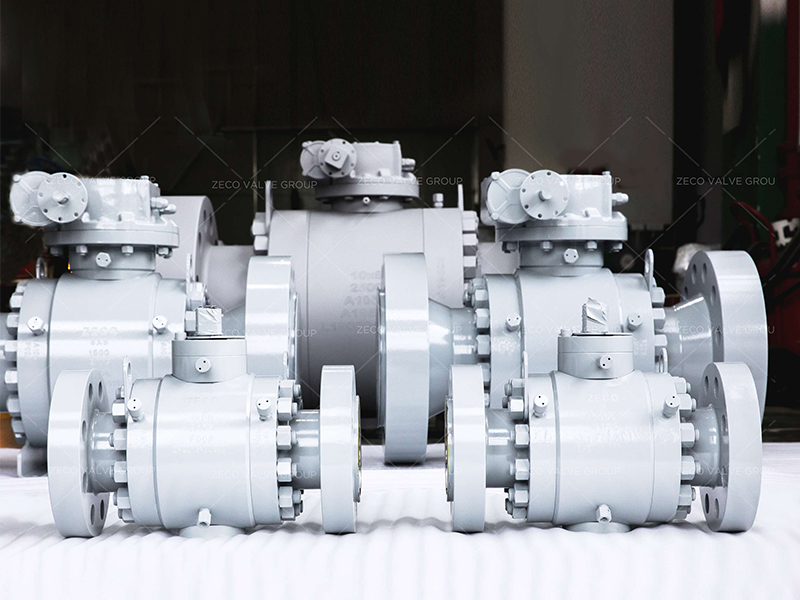

1. Trunnion Ball Valve

1.1 What is a Trunnion Mounted Ball Valve?

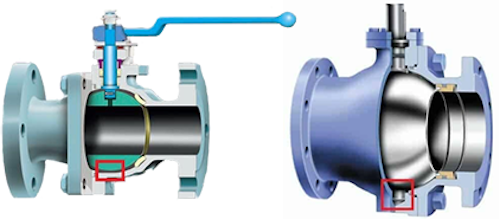

Trunnion Mounted Ball Valve is one type of ball valves, which is also called fixed ball valve. The ball of the trunnion mounted ball valve is fixed and it does not move when pressed. Trunnion Mounted Ball Valves are equipped with a floating seat. Under the action of the medium pressure, the seat will move to make the sealing ring tightly press on the sphere to ensure sealing. Bearings are usually installed on the upper and lower shafts of the sphere, and the operating torque is small, which is suitable for high pressure and large diameter valves.

1.2 Trunnion Mounted Ball Valve Assembly

The valve is usually assembled with the valve body as the reference part, in the order and method specified by the process. Before assembling, check the parts and components to avoid the parts that are not deburred and cleaned from entering the final assembly. During the assembly process, the parts should be handled with care to avoid bumping and scratching the processing personnel. The wrench used for tightening should not be too long to prevent the pre-tightening force from being too large and affecting the bolt strength. After the final assembly is realized, the control mechanism should be rotated to check whether the movement of the valve opening and closing parts is mobile and whether there is jamming.

1.3 Trunnion Ball Valve Design

The trunnion ball valve adopts the upper and lower stem fixed valve core (shaft support type) and movable sealing seat design, which is more stable in working. With the automatic compensation function, there is a great shear force and self-cleaning function when there is no gap between the two-way sealing valve seat. It is especially suitable for the on-off of fibers, suspensions with tiny solid particles, and viscous media.

1.4 Trunnion Mounted Ball Valve Characteristics and Performance

Trunnion mounted ball valves are suitable for various pipelines of medium and high pressure. They are used to cut off or connect medium in the pipeline. Different materials are selected. They can be applied to water, steam, oil, liquefied gas, natural gas, gas, nitric acid, acetic acid, oxidizing medium, urea, and other media respectively. They are widely used in the petrochemical industry, electric power, water conservancy, and other industries. The common driving modes of trunnion mounted ball valves are worm wheel drive, manual, electric, and pneumatic. Most trunnion mounted ball valves are flanged, but there are also trunnion mounted ball valves in welded form.

2.Ball Valve Floating Type

2.1 What is a Floating Ball Valve?

Floating ball valve is another type of ball valve. The ball of the floating ball valve is floating, and the valve seat is fixed. Under the action of the medium pressure, the ball can produce a certain displacement and press tightly on the sealing surface of the outlet end to ensure that the outlet end is sealed.

2.2 Floating Ball Valve Assembly

(1) Clean and check the removed parts. It is strongly recommended to replace the valve seat and valve cover gasket with a spare parts kit.

(2)Assemble in the reverse order of disassembly.

(3)Tighten the stem nut by using specified torque.

(4)After installing the control mechanism, input the corresponding signal to drive the valve core to rotate by rotating the valve stem to make the valve in the open and close position.

2.3 Floating Ball Valve Design

The floating ball valve has a simple structure and good sealing performance. However, the load of the sphere which bears the working medium is all transmitted to the outlet sealing ring. Therefore, it is necessary to consider whether the sealing ring material can withstand the working load of the sphere medium. When it is under higher pressure impact, the sphere may shift. As a result, this structure is generally used for medium and low-pressure ball valves.

2.4 Floating Ball Valve Characteristics and Performance

The overall characteristics of the ball valve floating type are small size, lightweight, simple structure, and a sphere with a free-floating function to better ensure sealing. The ball valve uses a ball with a circular through the hole as the opening and closing part, which rotates 0-90 degrees around the center of the stem under the drive of the valve stem to complete the opening and closing function. It has the characteristics of compact structure and fast switching. It can turn 90 degrees to close the valve and cut off the pipeline medium. The diameter of the spherical passage is the same as the diameter of the pipeline. The flow resistance is small and the flow capacity is large. The valve stem is downloaded, which prevents the accident of the valve stem penetration and ensures the safety of use.

Floating Ball Valve vs Trunnion

| Floating Ball Valve | Trunnion Ball Valve |

| The valve seats are fixed in the valve body | The ball is fixed in position by trunnions (bearing) and can only rotate |

| In the closed position, the ball can move a little bit in flow direction | The seats can move a little bit in flow direction |

| The ball is pressed against the downstream seat | The upstream seat is pressed against the ball |

| The system pressure acts on the whole circular area of the ball | The system pressure acts on the circular ring of the upstream seat |

| Usually DN 25 (NPS 1) up to DN 200 (NPS 8) for 150LB~600LB Usually DN25 (NPS 1) up to DN 50 (NPS 2) for 900LB~2500LB |

Suitable for All sizes and All Pressure Class |

| Suitable for medium and low-pressure applications as they are smaller in diameter and capable of bi-directional shutoff | Suitable for high-pressure applications and those that require bigger dimensions |

ZECO Valve is one of the professional & famous API 6D floating ball valve and trunnion ball valve manufacturers in China.

It is also important to choose a reliable Trunnion Ball Valve manufacturer & Floating Ball Valve Manufacturer.

If any inquiries, you can contact commercial@zecovalve.com