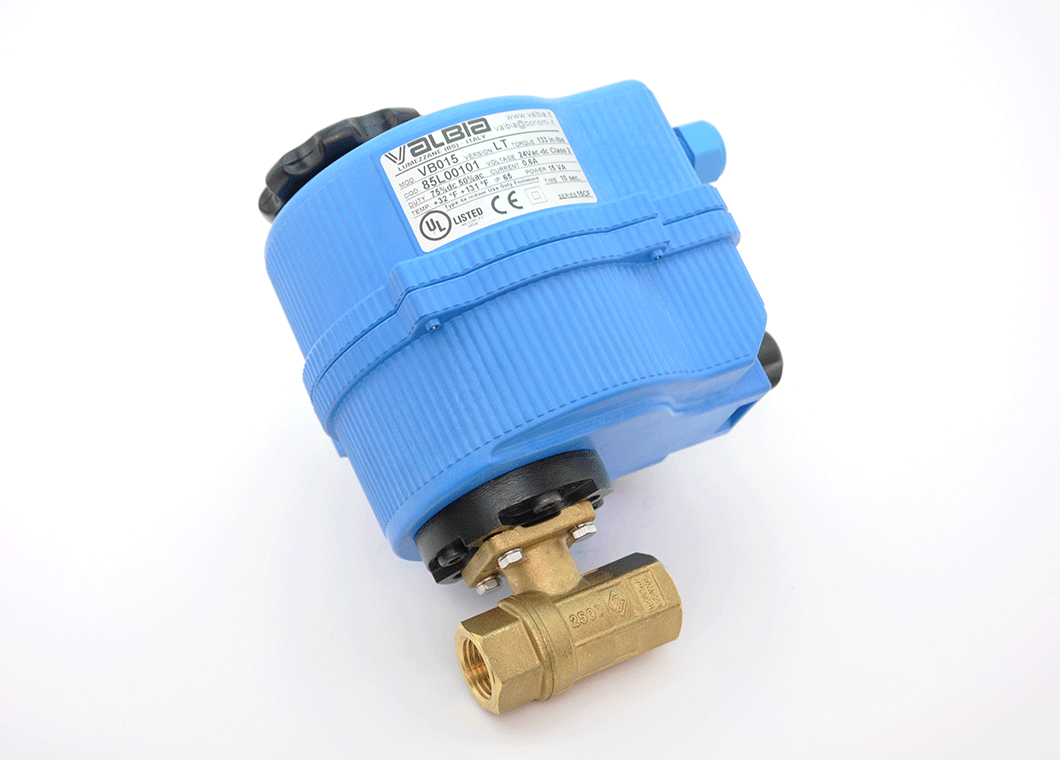

There are literally dozens of

types of valve actuators and valves. Wherever there is a valve, there must be a means to operate it. There are a range of options to do this that include gears, levers, and hand wheels. But valve actuators are one of more preferred choices for operating valves as they can be automated in order to eliminate the need for direct human interactions. Such remote and automatic operation is of particular importance in emergency-like scenarios where their shutdown mechanisms can reduce the need for human involvement in dangerous situations.

While safety is often the primary consideration for choosing to automate a valve, other reasons include:

- Need for reliable operation

- Greater control and process system performance

- Valve’s location in an inaccessible or remote area

- Most cost efficient solution available

Every valve actuator includes an input segment where the power supply and/or signal is received, an output, and a mechanism/circuitry that enables it to operate a desired valve. While the valve’s quality will depend upon its mechanical design, machining, and metallurgy, its real-world performance in the control loop will depend on the

valve actuator.

The Functions of the Valve Actuator

All actuators must be capable of the following functions:

- Move the closure mechanism (ball, disc, or plug). Actuators must have the appropriate directing controls and provide enough torque/thrust to move the closure mechanism in both mild and severe conditions.

- Hold the valve closed in directed position. Actuators mush have the necessary spring, fluid power, or mechanical stiffness to hold the valve closed even in throttling applications wherein fluids provide excessive torque against it.

- Properly seat the valve. For example, butterfly valves are considered properly seated when their disc has been positioned in the resilient seat or liner.

- Have a sound failure mode. In the event of a disaster of system failure, valve actuators must be equipped to be fully opened, closed, or stay as-is, depending on the application.

- Capable of rotating the rotation needed. Most valves will require either 90 or 180 degrees of rotation. Part of selecting the right valve actuator will depend on knowing the required rotational travel for use.

- Capable of operating under required speed. The cycle speed is how the valve actuator is regulated.

Selecting Types of Valve Actuators for Usage.

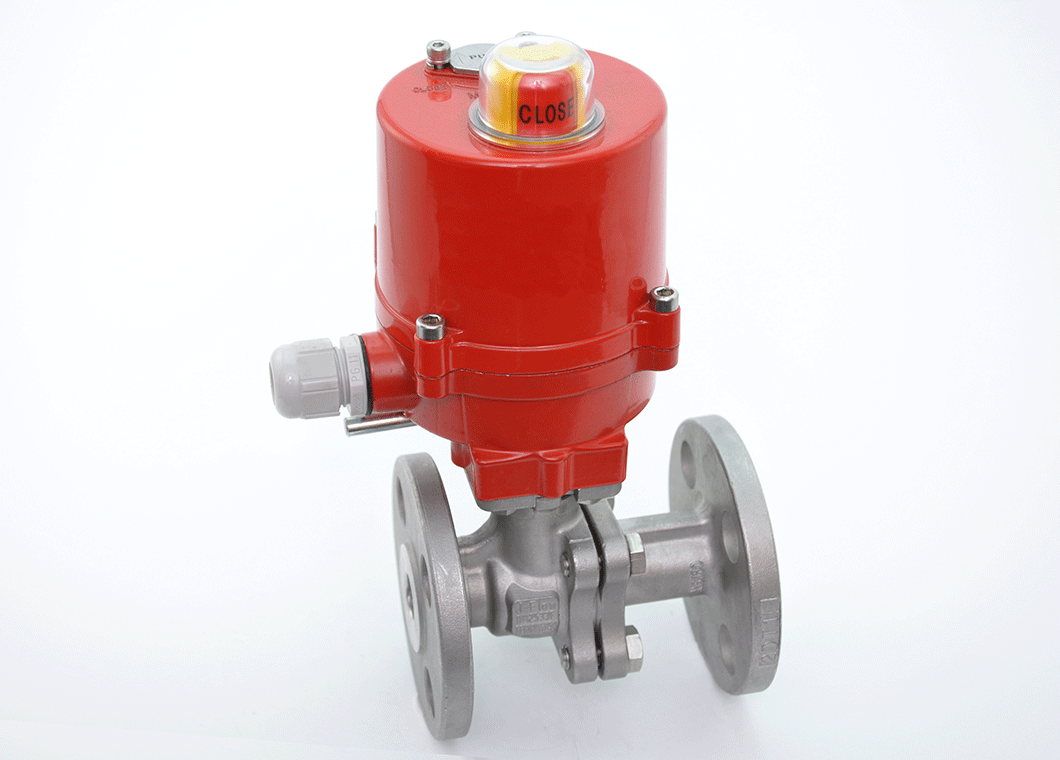

While there are four general types of

valve actuators, process engineers will generally find themselves choosing between either a pneumatically or electrically actuated valve for process systems. While each has its own advantages, choosing the valve actuator that best fits the application at hand will depend on several usage factors:

Compatibility (power source). The first determinant should be the available power source.

- For pneumatic actuators, an air supply between 40 and 120 psi will be needed. Higher air pressures can be difficult to acquire while lower pressures will need a larger diameter piston or diaphragm to create the required operating torque.

- For electric actuators, a 110 VAC power supply is generally required. However, a valve actuator may be purchased with other sized AC and DC motors.

Temperature range. While both types of a wide temperature range, pneumatic actuators are capable of operating up to 120 degrees Fahrenheit with the right seals, bearings, and grease. In contrast, electric actuators can withstand operations in temperatures of down to -40 degrees Fahrenheit.

Hazardous Areas. An electric

valve actuator is sometimes hard to justify within a hazardous environment, but may be required due to a lack of compressed air or the pneumatic style’s inability to operate as required. If so, an electric valve actuator must have a NEMA VII enclosure that’ll protect it from explosions. Because pneumatic actuators are so-called ‘explosion-proof’, they’re a more practical choice in such situations.